-100px

70px

The High Speed Cookies Packaging Machine is a fully automatic packaging line, completing a complete set of automatic packaging and boxing processes from cookie sorting to horizontal one-time packaging, then to counting and collection, followed by orderly sorting, and finally automatic box opening and boxing.

The milk powder packaging machine is an automated packaging equipment specifically used for powder materials. This machine can carry out packaging work in multiple channels (multiple columns) simultaneously, greatly improving production efficiency and packaging speed. It usually can automatically complete a series of operations such as measurement, bag making, filling and sealing, and can adjust the size and packaging capacity of the packaging bag according to different needs.

The automatic packaging machine for white sugar granules is a device used for automatic metering, filling, sealing and other packaging operations of white sugar granules. It is often used for small-dose and multi-column packaged white sugar products, such as sugar packets and coffee companions, with a packaging speed generally ranging from 35 to 50 cuts per minute.

The automatic sorting, boxing and packaging line for small tea bags in the shape of strips is a highly automated production line specifically designed for processing and packaging small tea bags in the shape of strips. This kind of packaging line usually integrates multiple functions, including but not limited to automatic sorting, counting, boxing, sealing and labeling steps, aiming to improve production efficiency, ensure packaging quality and reduce labor costs.

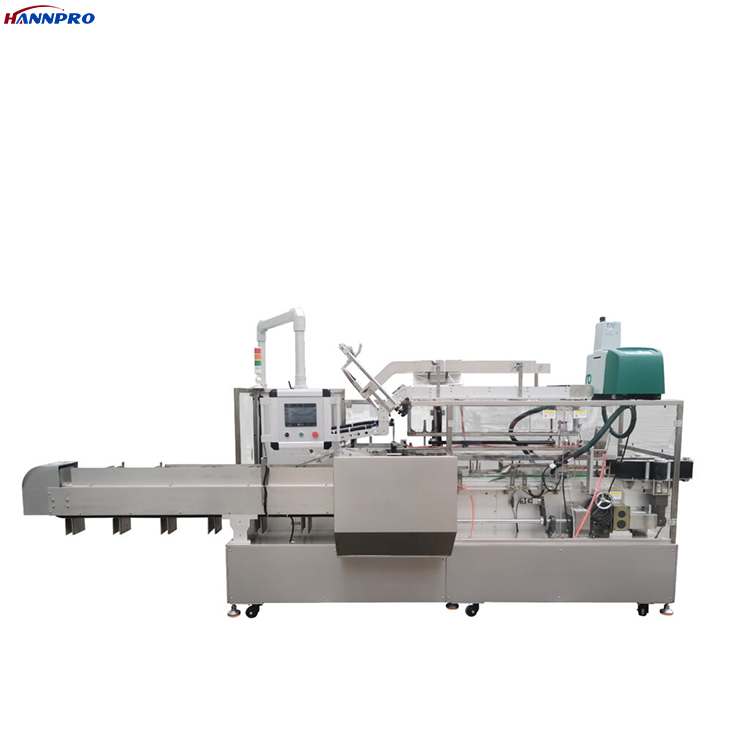

The horizontal cartoning machine is an automated device widely used in the pharmaceutical, food, cosmetics and other industries. It is mainly used to automatically load products into paper boxes and complete the sealing actions. This kind of machine is usually suitable for packaging products of different shapes such as bottles, boxes or bags.

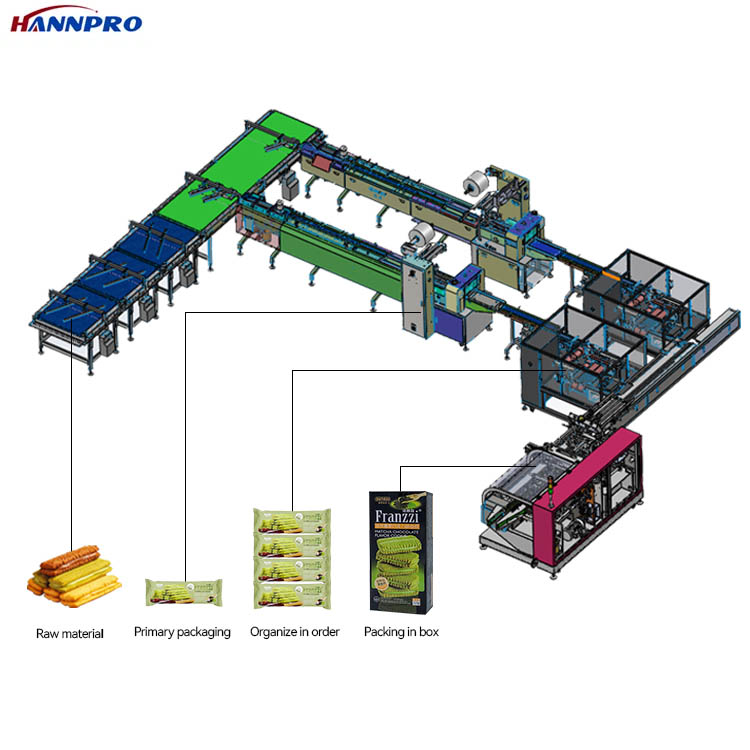

The Wafer biscuit automatic material sorting and packaging line is an automated solution specially designed to meet the efficient and precise packaging requirements of wafer biscuits. Such production lines usually integrate multiple functional modules, aiming to enhance production efficiency, reduce manual intervention and ensure the consistency of product quality.